How Much Silver is Recycled, Lost, or Expires with Use?

01/06/2025Daniel Fisher

Free & fully insured UK Delivery. Learn more

Secure & flexible payments. Learn more

Buyback Guarantee Learn more

Silver is a precious metal with a finite global supply — and unlike some resources, it isn’t always easy to replace or regenerate. One major factor that affects how much silver is actually available in the world at any given time is recycling.

Unlike gold, which is often stored and hoarded, silver is widely used in industries, electronics, and everyday products. That means a large portion of it ends up embedded in devices, worn away, or discarded after use

Because of this, recycling plays a crucial role in determining the total silver supply. And that supply is one of the key drivers of the silver price. When more silver is recovered and reused, it helps balance global demand. When silver is lost or unrecoverable, supply tightens, often contributing to price increases.

So, how much silver is actually recycled? How is it recovered? And how much of it is permanently lost or “expires” after use?

Recycling is a major component of the global silver supply chain. Unlike mined silver, which comes from finite underground deposits, recycled silver represents silver that’s already in circulation. This could be recovered from used products, industrial processes, and even old jewellery. But how much of the world’s silver actually comes from recycling?

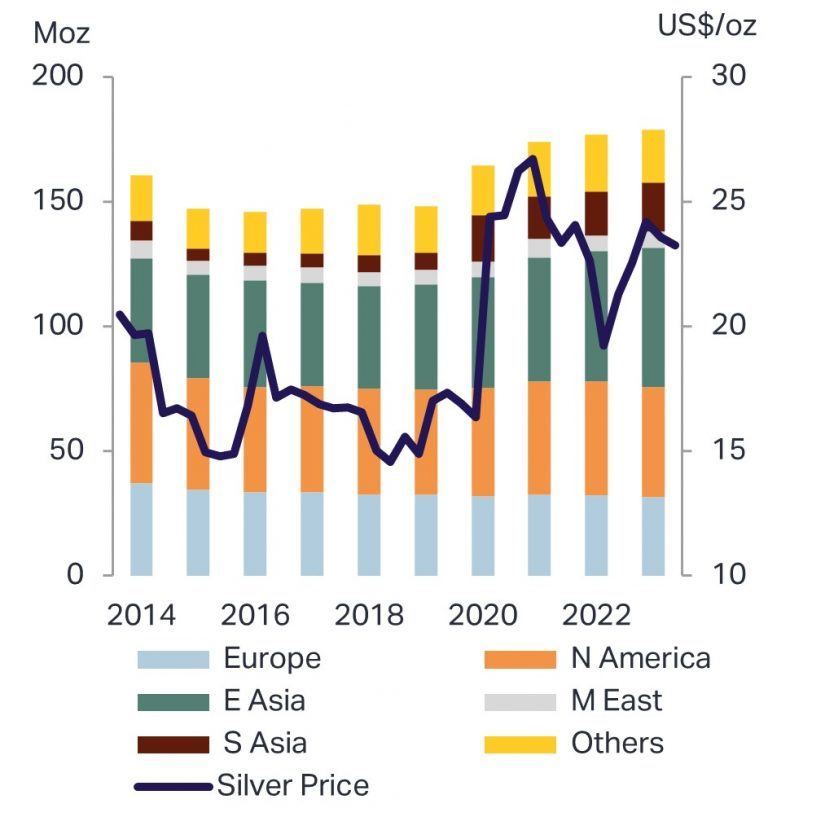

Each year, roughly 150–200 million ounces of silver are recycled worldwide. That’s about 15–20% of the total silver supply, according to recent data from industry sources like the Silver Institute. In some years, this percentage is even higher, especially when silver prices rise and make recycling more profitable. This amount is split globally, with East Asia and North America contributing the majority of recycled supply.

Silver recycling volumes can fluctuate due to market prices, industrial demand, and changes in technology. For example:

Over the past decade, the share of recycled silver has remained relatively stable, but it’s increasingly vital as mining becomes more challenging and demand continues to grow.

Recycled silver doesn’t come from just one place, it comes from a variety of sources, each contributing to the overall flow of secondary silver:

Each of these sources adds back silver into the economy, but the amount recycled depends on how easily (and profitably) it can be recovered.

Material and statistics in this section were adapted in part from the Silver Institute’s World Silver Survey 2023.

Silver recycling isn’t just about tossing old jewellery into a furnace. It’s a diverse process that depends heavily on where the silver is coming from. Whether it’s an old necklace, a circuit board, or leftover industrial material, the method for recovering silver varies.

However, all recycling methods share a common goal: to extract usable, high-purity silver that can be reintroduced into the supply chain. Here are the three possible methods in order of difficulty. Melting works well for pure silver items, smelting handles more complex mixtures, and chemical methods recover silver from liquid waste streams.

One of the simplest and most common methods for recycling silver is melting. This is typically used for relatively pure forms of silver, such as jewellery, coins, and silverware.

Melting is efficient, cost-effective, and ideal for large, solid items with high silver content. However, it’s not suitable for silver mixed with other complex materials, that’s where smelting and chemical processes come in.

Smelting is used when silver is bound up with other metals or materials, especially in electronic waste or mining byproducts. It’s more involved than simple melting.

Smelting is essential for recovering silver from more complex or contaminated sources, though it tends to be more energy-intensive and costly than melting.

When silver exists in very small quantities or in liquid solutions (such as in photographic waste, x-ray film processing, or certain industrial uses), chemical methods are used.

Chemical recovery is highly effective for industrial facilities where silver-containing solutions are a regular byproduct. It requires careful handling and technical expertise but offers a high yield in settings where mechanical recovery isn’t feasible.

One of silver’s most valuable properties, aside from its beauty and conductivity, is that it’s infinitely recyclable. This means silver doesn’t degrade or lose its essential qualities during the recycling process. As long as it’s recovered properly, silver can be melted, refined, and reused over and over again without any loss in quality.

In theory, a single ounce of silver could be recycled hundreds or even thousands of times throughout human history, with some of the silver in circulation today very possibly having been used in ancient coins, jewellery, or artifacts.

However, while silver itself is endlessly recyclable, in practical terms, there are a few barriers that limit how often any one piece of silver actually gets recycled:

Still, when recovered, silver is just as valuable and usable as newly mined silver. This makes it a truly sustainable material, provided it’s actually collected and recycled properly.

Free ultimate guide for keen precious metals investor

Although silver is infinitely recyclable in theory, a significant portion of it becomes unrecoverable in practice. This doesn’t mean it disappears, but it becomes so dispersed, degraded, or embedded in other materials that recycling is no longer economically or technically feasible. This “lost” or “expired” silver contributes to a shrinking available supply, which in turn impacts silver spot prices and long-term availability. The nature of this lost silver makes it incredibly difficult to measure exactly how much silver leaves the supply chain each year.

There are four main ways where and how silver gets lost:

Silver is used heavily in industrial applications, especially for its excellent electrical and thermal conductivity, reflectivity, and antibacterial properties. But in many of these applications, silver is used in very small amounts or in forms that are difficult to recover.

Examples include:

The result: silver that is functionally spent (or expired) and unlikely to re-enter the supply chain.

Even in everyday items like jewellery, coins, and silverware, silver can be gradually lost over time through abrasion and corrosion.

While these losses are small individually, they add up over time, especially when silver ends up in landfills or households where it’s never reclaimed.

One of the largest modern sources of unrecovered silver is electronic waste. Smartphones, tablets, computers, and other electronics all contain trace amounts of silver in components like switches, contacts, and circuit boards.

However:

Despite growing awareness, only a fraction of the world’s e-waste is properly recycled. As technology reduces the cost of production, the culture of buying new tech and discarding the old, means it can be economically unviable to recycle. This leads to a substantial and growing loss of silver year after year.

Some silver is lost in forms that are literally flushed away or dispersed into the environment:

This type of loss is especially problematic because it spreads silver in ways that make it nearly impossible to reclaim, effectively removing it from the usable supply.

Despite silver’s high value and full recyclability, a surprising amount never makes it back into the supply chain. Here’s why:

In short, it’s not a question of whether silver can be recycled, but whether it’s practical, profitable, or prioritized.

As demand for silver continues to grow, especially in green technologies, electronics, and healthcare, recycling will play an increasingly critical role in keeping supply sustainable. With finite mining resources and more silver being lost through use, the future of silver recycling will depend on innovation, policy, and public awareness.

Researchers and recycling companies are developing more efficient and cost-effective methods for silver recovery, especially from complex sources like e-waste and solar panels. Emerging techniques include:

These technologies aim to make silver recovery faster, cheaper, and cleaner, which could drastically improve recycling volumes in the coming decades.

Improving how we handle electronic waste is essential. Ever-increasing environmental awareness will continue to drive more countries to introduce:

As infrastructure catches up, more of the silver in discarded electronics could be reclaimed.

Governments, companies, and consumers are becoming more aware of the environmental and economic value of recycling. Silver is a perfect candidate for a circular economy, where materials are kept in use for as long as possible.

By increasing recycling rates, we can:

In the future, recycling may not just be a backup to mining. It could become the primary source of silver, keeping this precious resource in use for generations to come.

Around 150 to 200 million ounces of silver are recycled globally each year, making up roughly 15–20% of the total annual silver supply.

Yes, silver can be recycled indefinitely without losing quality, as long as it is properly recovered and refined.

Silver is often lost when it’s used in small amounts in electronics, medical products, or solar panels, where recovery is either too complex or not cost-effective.

Most recycled silver comes from scrap jewellery, silverware, industrial byproducts, and electronic waste like circuit boards and connectors.

Many silver-containing items are thrown away, dispersed, or embedded in materials that are too expensive to process, limiting overall recycling rates.

Live Gold Spot Price in Sterling. Gold is one of the densest of all metals. It is a good conductor of heat and electricity. It is also soft and the most malleable and ductile of the elements; an ounce (31.1 grams; gold is weighed in troy ounces) can be beaten out to 187 square feet (about 17 square metres) in extremely thin sheets called gold leaf.

Live Silver Spot Price in Sterling. Silver (Ag), chemical element, a white lustrous metal valued for its decorative beauty and electrical conductivity. Silver is located in Group 11 (Ib) and Period 5 of the periodic table, between copper (Period 4) and gold (Period 6), and its physical and chemical properties are intermediate between those two metals.